معلومات ذات صله

استشر الولايات المتحدة

بصفتنا مصنعًا عالميًا رائدًا لمعدات التكسير والطحن ، فإننا نقدم حلولًا متطورة وعقلانية لأي متطلبات لتقليل الحجم ، بما في ذلك إنتاج المحاجر والركام والطحن ومحطة تكسير الحجارة الكاملة. نقوم أيضًا بتوريد الكسارات والمطاحن الفردية وكذلك قطع غيارها.

MASTER YOUR OUTPUT CRUSHER SELECTION QUICK GUIDE

Recommendations: Best (B), Good (G), Possible (P) A typical example of primary crushing is reducing topsize from 900 to 300 mm A typical example of secondary crushing isthe crusher and scalp out fi nes Primary gyratory crushers – ideally suited to all highcapacity primary hard rock crushing applications Jaw crushers – we have more installedCrushing and Screening Handbook AusIMM

Crushers All crusher types for your reduction needs minevik

There are two basic types of jaw crushers: single toggle and double toggle In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation causes, along with the toggle plate, a compressive action A double toggle crusher has two shafts and two toggle plates The first shaft is a pivoting shaft on the top ofCrusher Type Selection Gyratory and jaw crushers represent the bulk of primary crushers used at mining operations today Impact crusher is a kind of stone crushers that uses impact force to crush materials It has the feature of big crushing ratios, high output,Equipment Selection For Crushing Plant Yeco Machinery

Basalt Stone Crushing Plant, Stone Crusher Selection

The equipment combination (four section type) of basalt stone crushing production line is generally as follows: (1) Feeding: vibrating feeder (2) Coarse crushing: jaw crusher with feed size of 1500500mm, crushing toThere are several types of industrial crushers available to industrial buyers These types include: Cone or gyratory crushers insert feed via a coneshape bowl and crush it with a spinning or gyrating head HPGR (high pressure grinding rollers), roll/roller crushers, or mineral sizers use two large rollers or a roller and a flat surfaceCrushers Selection Guide: Types, Features, Applications

Crushing and Screening Handbook AusIMM

the crusher and scalp out fi nes Primary gyratory crushers – ideally suited to all highcapacity primary hard rock crushing applications Jaw crushers – we have more installed jaw crushers than anyone in the world The leading choice due to their high reduction ratio and heavy duty design Cone crushers – capacities available to suit all2020年3月19日· Best suited for secondary crushing applications, cone crushers are designed to crush presized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher Cone crushers can form finished products down to 12mm or less Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, butSelecting the right crusher for your operations Quarry

Selecting the Right Crushing Equipment | AggNet

2015年10月28日· Gerry Mangrich, regional sales manager aggregate processing with McLanahan Corp, outlines the main crushing stages and examines the key characteristics of the main crusher types Most aggregate producers are well acquainted with the selection of crushing equipment and know it is possible to select a piece of equipment based2023年4月13日· Raymond mill is mainly located behind the cone crusher in quartz stone processing, used to achieve grinding production of quartz stoneThis machine adopts a sealed production structure and has good environmental performance Advantages Strong wear resistance: The main components of the grinder are all made of highqualitySelection Of Quartz Stone Crushing And Grinding Equipment

Crusher; Crushing; and Classification Equipment | PPT SlideShare

2020年11月7日· Mineral Processing: Crusher and Crushing; Secondary and Tertiary Crushing Circuits; Types of Crusher; Types of Crushing; Types of Jaw Crushers; Impact Crusher; Types of Cone Crushers; Ball Mill; BEST STONE MANUFACTURERS; Local Quality and High quality ; International and Country/Hand made ClassificationThe global stonecrushing equipment market was valued at USD 555 billion in 2021 and is expected to surpass a net valuation of USD 845 billion by 2027 end, registering a solid CAGR growth of 725% over the forecast period Due to the COVID19 pandemic, many industries, including the construction industry, witnessed a slump in investment in 2020Stone Crushing Equipment Market Size & Share Analysis

Factors to Consider When Selecting the Proper Roll

2019年11月21日· By: Geordie Edmiston November 21, 2019 Selecting the proper Roll Crusher for an application depends on many factors When selecting the proper Roll Crusher for an application, you must fully2023年2月23日· When designing an aggregate crushing plant, there are several factors that must be taken into account to ensure that the plant meets the desired performance and output goals These factors include:The Ultimate Guide to Designing an Efficient

Correct Selection Of marble Crushing Equipment

2022年11月19日· Marble, also known as cloud stone, is recrystallized limestone Generally refers to marble , limestone, dolomite, and skarn and marble formed by different alterations of carbonate rocks The general2016年2月28日· Crushing Equipment Selection In open pit quarry operations the loading of the blasted rock for transportation to the primary crusher house involves either powershovels Any size of primary crusher may be used for handloaded rock; it all depends upon how much secondary shooting, and hand sledging, the operator feels he can afford SoCrushing Equipment Selection 911 Metallurgist

Factors of Crusher Selection Sand & Stone CMPA

2009年2月4日· Crusher capacities are based on a graded feed from the maximum size down to a minimum size approximately equivalent to the CSS For instance, if the ROQ feed is from a gravel pit and you are producing a product less than 20mm is size and the raw feed contains 70% of natural occurring material of less than 20mm, this leaves only 30% to be2015年12月16日· Donald RWoods Here is a list of Rules of Thumb often used in Rock Crushing and around Crushers: Crusher Selection For a hard rock mine application below 600 tonnes/hour, select a jaw as the primary crusher Over 1,000 tph, select a gyratory crusher Between these capacities, you have a choiceRock Crushing Rule of Thumb 911 Metallurgist

(PDF) Design and Performance Evaluation of a Stone Crusher

2021年10月7日· The machine was fabricated using locally available materials The fabricated stone crusher was tested and the actual capacity was found to be 301 kg/h with a throughput efficiency of 754 % The2019年11月11日· Crushed stone often has an angular and jagged edge because of the crushing process Gravel, on the other hand, typically has a very smooth texture and surface because of the natural weathering and wear of being exposed to running water Unlike crushed stone, gravel is usually sold and used in its natural stateThe Complete Guide to Crushed Stone and Gravel

Stone Crusher Plant Setup Machinery Partner

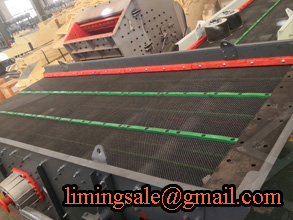

The stone crusher plant consists of a crushing setup of excavators, feeders, primary and secondary crushers and screeners They all work together to crush stone as efficiently as possible Conveyors connect everything, moving the crushed material from one station to the next Stone crusher plant equipment is divided into two categories:2022年11月6日· Before we introduce the stone crusher selection procedure we must first gain an indepth understanding of the most popular stone crushers, which will allow anyone to pick in the future The most commonly used stone crushers mainly include jaw crushers, cone crushers, impact crushers as well as fine crushersHow To Choose Stone Crusher SlideServe